Concrete Pouring & Curing in Schenectady: Cold Weather Tips

Pouring Concrete Schenectady

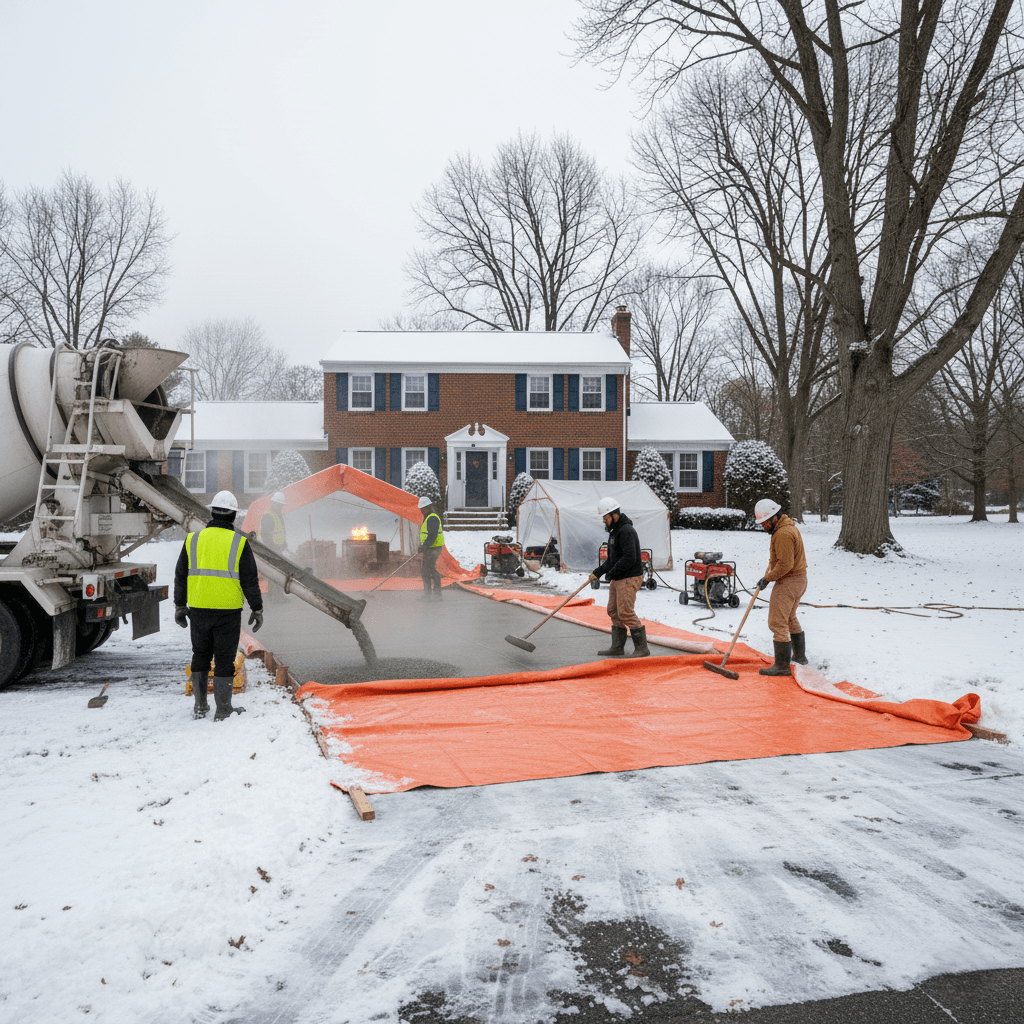

The extreme winter in Schenectady, New York, can create many problems when it comes to working with concrete, and it is common for the temperature to drop below freezing from December to March. It is very important to understand how cold weather affects the process of pouring concrete so that local homeowners and builders can plan their winter construction projects accordingly. Throughout the winter, a fluctuation in temperature from 16°F to 41°F will have an impact on all of the chemical reactions that are necessary for developing the strength of the concrete. There are many professional techniques and types of specialized equipment available that make it possible to complete a successful installation of concrete in spite of the extreme weather. Planning will keep your project on track by preventing delays, which can be very expensive, and will also provide you with a result that lasts over time, regardless of the season.

Understanding Cold Weather’s Impact on Concrete Chemistry

The cold temperatures significantly hinder the hydration reaction, which is a chemical reaction that causes liquid concrete to become solid and strong; this reaction works best at temperatures between 50°F and 60°F (and virtually ceases when the temperature falls below 40°F). This presents a significant challenge to completing successful concrete placements in the City of Schenectady, NY, where the average temperature in January ranges from 16.9°F to 28.6°F. When the concrete freezes before it reaches its full strength, the expansion of water will cause lasting damage to the concrete and reduce the strength of the concrete by up to 50%. The most critical period of time is in the first 24 to 48 hours after pouring the concrete, when the temperature needs to be maintained properly.

Understanding how cold weather affects chemistry will help contractors and homeowners make better-informed decisions regarding their winter concrete projects.

Important Temperature Ranges for Concrete Success

In order to achieve enough strength for the concrete to resist freezing, the temperature of the concrete must be kept above 40°F during the first curing period. Industry standards suggest that the temperature of the concrete should be maintained at 50°F or higher during the first 48 hours after the placement of the concrete. After the concrete has achieved 500 PSI compressive strength (which usually takes place within 2 days at normal temperatures), it becomes much less susceptible to freeze damage.

Maintaining the correct temperature during the curing process is crucial to developing the required strength in the concrete and will prevent costly failures. The location of properties near Union College and in the downtown Schenectady area necessitates close observation of the local microclimate conditions that will affect the temperature of the concrete, which may vary from what is reported in general weather reports.

Strategies to Prepare for the Pour of Concrete in the Winter

Preparing for successful winter concrete projects begins with a thorough approach that addresses ground conditions, materials, and equipment. Before the concrete is poured, the frozen ground must be thawed with the use of heaters because a frozen surface will cause rapid heat loss and create problems of settlement when the spring thaw occurs. In most cases, thawing the ground will take 24 to 48 hours, depending upon the condition of the soil.

Using hot water to mix the concrete becomes an essential component for obtaining the right temperature of the concrete for winter pours. Typically, ready-mixed suppliers will deliver the concrete at a temperature of 65° F; however, there will be considerable heat loss during transportation, and it will need to be carefully timed and insulated. Storing aggregate and cement in a heated area before mixing will also assist in maintaining the optimal temperature during the entire process.

Ground Preparation and Equipment Needs

Windbreaks are used to protect fresh concrete from losing temperature rapidly and moisture due to the extreme cold and high winds that are common along the Mohawk River in the Schenectady area. For larger projects, heated enclosures provide a controlled environment to ensure that the temperature remains constant during the curing period. To prevent tools and forms from becoming too cold and causing the fresh concrete to be shocked, thereby affecting the quality, equipment must be stored in a heated area.

The timing of projects becomes critical in the winter, as weather forecasts will determine the optimal time to perform the pour. Depending upon the elevation of the project, the proximity to Central Park, and other environmental factors, projects in the elevated areas of Schenectady may have different environmental conditions than those located at the level of the Mohawk River. Therefore, each project will require site-specific weather monitoring for a successful outcome.

Modifications to Concrete Mixes for Cold Weather Performance

For winter concrete mixes, the mixes must be adjusted to address the challenges associated with cold weather. Accelerator additives are added to increase the rate of chemical reaction, thus shortening the time that the concrete takes to set and increasing the rate at which the concrete develops its strength in cold weather conditions. However, it should be noted that accelerator additives containing calcium chloride should never be used when steel reinforcement is involved, as they can cause corrosion problems.

Air entrainment is extremely important in Schenectady’s freeze/thaw climate, as it provides microscopic air bubbles that allow ice to expand without causing structural damage to the concrete. Low-slump concrete with lower water content reduces bleeding and reduces the time it takes for the concrete to set, resulting in improved performance in cold weather conditions. The specification of the type of cement and admixture used will also result in improved performance in cold weather conditions.

Professional Design of Mixes for Cold Weather

The design of the mix for winter concrete is based on the expected weather conditions and the specifications of the project by experienced suppliers of concrete. Increasing the amount of cement in the mix produces more heat of hydration and, therefore, will keep the temperature of the concrete stable during the curing process. Specialized cold weather admixtures provide frost protection without compromising the long term durability or the strength characteristics of the concrete.

Contractors who work in the Stockade District are aware of the regional climate challenges and design mixes for the Capital Region that meet the specific needs of the client. Working with knowledgeable suppliers will ensure the correct material is selected for the specific project requirements and weather conditions.

Protection of the Concrete During the Curing Process

During the curing process, the concrete blanket will provide thermal protection to the concrete, trapping the heat of hydration generated by the curing process and preventing rapid temperature loss, thus allowing the concrete to develop its strength. Blankets must remain in place for a specified minimum period of time, which will depend upon the temperature conditions and the requirements of the concrete.

Enclosures for larger projects provide total protection against adverse weather conditions and provide a controlled environment that eliminates the variables of weather conditions. The enclosure must be windproof and waterproof, and must provide adequate ventilation to prevent carbonation from the heating equipment. Using steam to inject heat into the enclosure will maintain the humidity level and provide additional heat, especially useful when the curing process will extend over a longer period of time.

Monitoring and Documenting Temperature

Continuous temperature monitoring is necessary to ensure that the concrete is kept in the proper conditions throughout the curing process. Thermometers and infrared devices will provide accurate readings and help contractors to make informed decisions concerning protective methods. Documenting the temperature and the weather conditions will provide valuable documentation for quality control and future project planning.

Documentation of temperature readings and weather conditions will help to identify patterns and potential problems before they become serious. Several successful contractors document their winter projects and build databases of effective strategies for specific weather conditions and project types found in the Schenectady area.

Challenges and Solutions for Common Problems Experienced During Winter Pours

Delivering the concrete at the right time becomes very important in winter pours, as the temperature of the concrete will drop approximately one-fourth of the difference in temperature between the concrete and the air per hour of delivery. Coordinating with the supplier will ensure that the concrete is delivered at the right temperature and minimize heat loss before placement. Rapidly placing and immediately protecting the finished concrete will also prevent temperature loss during the finishing operations.

As a result of extended setting times in cold weather, finishing operations may be delayed, and adequate lighting will be needed for possible evening work. Contractors must coordinate the weather windows with the project requirements and may need to adjust the scope or timeline of the project to produce a successful outcome. Communication among all stakeholders is very important to coordinate the winter concrete projects successfully.

Quality Control in Cold Weather

Testing procedures must be modified to reflect the slower rate of strength gain and extended protection periods of the concrete in cold weather. Samples taken from the cylinder tests must be protected in the same manner as the main pour to ensure that the results of the tests reflect the actual performance of the concrete. Testing equipment may also require calibration adjustments to operate properly in cold weather.

Visual inspections of the surface of the concrete will help to identify problems early in the process. Cracks on the surface, color changes, or difficulties in finishing often indicate problems related to temperature that must be addressed immediately. The historic neighborhoods in Schenectady may have specific aesthetic requirements that must be considered when performing finishing techniques in cold weather.

Cost Implications of Winter Concrete Projects

Due to increased materials, labor, and equipment needs, winter concrete projects typically cost 10-30% more than similar projects completed in moderate weather conditions. Increased costs include heating costs, specialized materials, and extended protection periods. Although there may be cost benefits from scheduling flexibility during the winter months due to decreased competition and availability of contractors, emergency heating equipment rental, additional labor for temperature monitoring, and extended project timelines will impact the budget of the project. It is recommended that the costs of these items be planned ahead of time to avoid unexpected increases in costs and to ensure that there are sufficient resources available to complete the project successfully. Many contractors also develop winter pricing schedules that reflect additional requirements yet remain competitive.

Seasonal Planning and Scheduling

The ideal window for pouring concrete in Schenectady occurs during late Spring through early Fall, when the temperature remains consistently above 40° F. However, with proper planning and protective measures, concrete can still be successfully placed during the winter months. By understanding the seasonal weather patterns, contractors can schedule their projects during the most favorable conditions while maintaining the flexibility to respond to urgent repair needs.

By monitoring long-range weather forecasts, contractors can identify suitable windows for winter concrete work and schedule their projects accordingly or prepare protective strategies for prolonged cold snaps. Urban heat islands, such as those found around properties near Proctor’s Theater and downtown locations, may provide a slightly warmer microclimate than surrounding rural areas.

Recommended Best Practices for Successful Winter Concrete Projects in Schenectady

Successful winter concrete projects require a comprehensive planning process that includes the correct materials and diligent temperature monitoring throughout the curing process. Local contractors with experience working in the region’s climate will employ the proper techniques and protection methods to ensure a successful project. Providing ample time for ordering materials, renting equipment, and monitoring the weather will ensure success in winter concrete projects.

Excellent communication between property owners, contractors, and suppliers is essential in winter concrete projects. Weather-related delays or changes to the project scope require flexibility from all stakeholders to ensure a successful outcome. An understanding of the limitations imposed by cold weather will establish realistic expectations while maintaining quality standards during the difficult cold weather conditions.

At Schenectady Concrete Works, we specialize in winter concrete projects and recognize the unique challenges faced by local property owners during the cold winter months. With our knowledge of the regional climate and proven cold-weather techniques, we guarantee the successful pouring of your concrete project regardless of the seasonal challenges presented by the harsh Capital Region winters.